What Are Wood Floor Trusses?

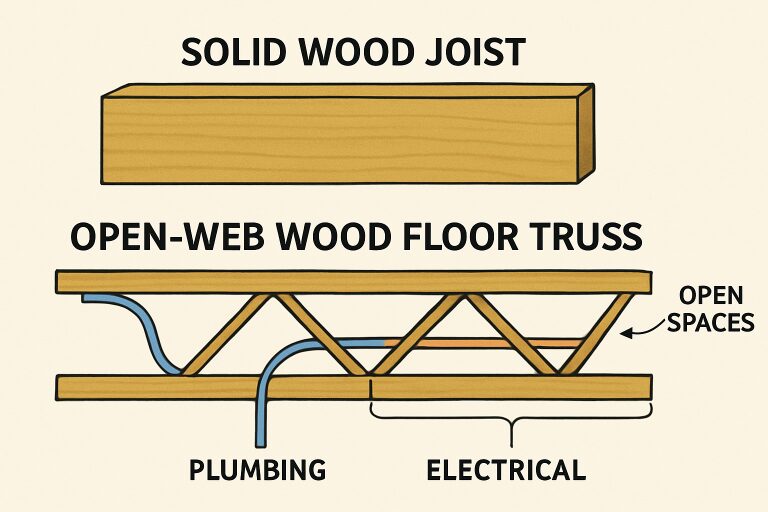

Wood floor trusses support wide-span floors in modern construction, allowing for open layouts and increased flexibility. Their precise, engineered design optimizes strength while reducing weight, and their open-web structure facilitates routing utilities without extra modifications. They are available through specialized suppliers to meet diverse design needs.

Top Advantages Of Floor Trusses

The use of wood floor trusses has increased rapidly because of their benefits. They can span longer distances without support, creating larger, flexible spaces. They use less lumber, reducing waste, and are easy to install due to their uniformity. Their open web design makes it easier for contractors to run ductwork and wiring, speeding up construction and reducing costs. For projects requiring both efficiency and adaptability, solutions like wood floor trusses California provide a reliable option for builders and designers alike. These systems improve overall building performance and contribute to long-term cost savings. They are preferred for modern construction projects because they integrate strength with design flexibility.

Common Wood Floor Truss Profiles

Selecting the right truss profile is crucial for optimal floor system performance. Parallel chord trusses are common, supporting extended spans with easy installation. Raised-heel trusses, with greater depth at wall intersections, facilitate insulation and meet energy standards. Scissor trusses are used for sloped or vaulted ceilings. Each profile offers benefits for vibration control, load sharing, and flexibility. Consulting a truss manufacturer ensures the profile matches project goals.

Important Design Considerations

Specifying wood floor trusses involves evaluating key factors like span, loads, deflection limits, and lumber grade. Early consultation with a structural engineer is recommended, as local codes may set minimum load and fire resistance standards. Designing truss layouts with future expansion in mind can save time and resources, ensuring adaptability to evolving building needs.

Truss vs. Traditional Joist Comparison

Wood floor trusses offer greater spans with fewer supports, allowing more open rooms. They simplify mechanical routing by eliminating drilling or furring. Engineered trusses can be more expensive upfront but recover savings through reduced labor, finishing, and workflow efficiencies. They provide superior vibration control, reduced floor squeaks, and more robust long-term performance.

Coordination With Other Trades

Effective coordination with trades is one of the key differentiators when comparing floor trusses to conventional joist systems. The truss’s open framework simplifies the sequencing of construction tasks, enabling electricians, plumbers, and HVAC contractors to complete their work faster and with lower risk of damaging the structure. Early collaboration among designers, truss suppliers, and subcontractors prevents onsite conflicts and change orders, ensuring the installation process stays on track and within budget.

Code Requirements And Industry News

Staying updated on building codes is vital for projects using wood floor trusses, as codes evolve with advances in materials, sustainability, and safety. Resources offer updates on requirements and best practices. Industry trends emphasize sourcing sustainable materials and efficient framing, favoring engineered wood. Supply chain issues highlight the importance of reliable truss suppliers who meet deadlines despite market fluctuations.

Maintenance And Long-Term Performance

Wood floor trusses are built to last, but regular visual checks help spot early moisture, rot, or pests. To prolong their lifespan, keep the crawlspace or basement dry and ventilated. Promptly fixing issues prevents costly repairs. Good design and quality installation ensure long-term performance. Partner with trusted suppliers and stay updated on standards to keep your floor system safe and stable.

Final Takeaway

Wood floor trusses have become a cornerstone of modern construction, offering the strength, adaptability, and efficiency that builders and designers demand. Their ability to support open layouts, streamline mechanical installations, and reduce waste makes them a smart alternative to traditional joist systems. With options, projects can achieve both structural reliability and long-term cost savings. By considering design factors, coordinating with trades, and maintaining best practices, builders can maximize the performance and lifespan of these engineered systems. Ultimately, wood floor trusses deliver a balance of durability, flexibility, and sustainability—qualities essential for today’s evolving construction needs.