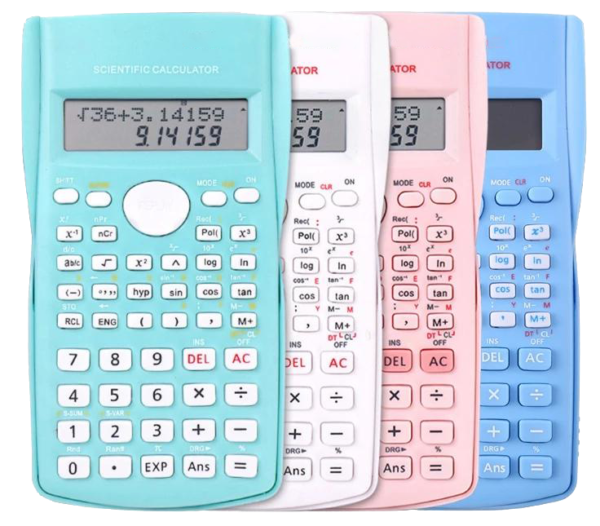

This guide will tells why plastic injection molding matters for branded electronics. Logo electronics, such as custom calculators, promotional gadgets, and desktop accessories, make great promotional products. Companies use them as trade-show promotional products, retail items, or corporate gifts to help their brand remain in front of individuals’ eyes long after the event.

Behind every glossy calculator or logo-imprinted electronic device is a fundamental manufacturing process: plastic injection molding. Branding with a trustworthy China plastic injection molding supplier allows companies to transform creative concepts into inexpensive, quality products by the batch.

China has today become the world’s precision injection molding hub with its sophistication in supply chain, quality equipment, and affordability. For those firms intending to manufacture custom electronics enclosures, an understanding of how these factories work can mean the difference between a launch success and a costly failure.

1. The Complete Development Journey From Idea to Product

Here’s the complete injection molding process from concept to custom product.

1) Product Concept & Industrial Design

The journey begins with design. Brands make early choices about product size, key layout, and location of the company’s logo. Continued collaboration with an established Chinese maker early on ensures that the design is injection molding-compatible—to avoid expensive rework later on. Being able to accept 3D CAD drawings, preferred color samples, and logo information enables engineers to build the design into a production-friendly format.

2) Prototyping and Mold Design

After concept approval, construction typically involves 3D-printing a prototype for ergonomics and aesthetics testing. After approval, they move on to precision mold design. Calculator cases typically utilize high-quality tool steels like H13 or P20 to survive millions of injection cycles. Advanced mold-flow analysis computer software simulates the flow of plastic when molten, preventing such defects as warping or sink marks.

3) Material Selection

Choosing the right plastic is essential for durability and appearance

ABS: Excellent impact resistance and smooth finish—ideal for calculator shells.

PC (Polycarbonate): High transparency and heat resistance for display windows.

PC/ABS Blends: Combine strength with an attractive surface for high-end electronics.

A capable China plastic injection molding manufacturer will advise on UL ratings, RoHS compliance, and color-matching to your brand palette.

4) Mass Production & Quality Control

Once molds are completed, computer-controlled injection machines heat and fill the mold cavities with plastic to a controlled pressure and temperature. Shot-to-shot consistency is controlled by experienced technicians. Quality groups check for dimensional tolerance, surface finish, and strength. For branded calculators, inspection also covers screen fit, button actuation, and battery compartment tolerances.

2. Branding Options for Custom Calculator

A calculator is more than a functional tool, it’s a brand ambassador. Here are popular branding techniques:

Silk Screen Printing: Cost-effective for single-color logos.

Pad (Tampo) Printing: Best for multi-color logos and odd curves.

Laser Engraving: Creates a permanent, high-quality look on metal or coated surfaces.

UV Printing: Enables full-color, photo-quality graphics on plastic in one step.

Color matching is equally important. Injection molders can even color resin pellets to your corporate Pantone color, which will ensure brand consistency on every unit. Packaging such as printed cartons or eco-friendly pouches adds another level of branding for retail or promotion distribution.

3. How to Choosing the Right Chinese Injection Molding Partner?

Selecting the right China plastic injection molding manufacturer is as important as the design itself.

Evaluate Certifications

Look for ISO 9001 or ISO 14001 certifications to confirm robust quality and environmental management. For electronics sold in the EU or U.S., RoHS compliance is critical.

Inspect Prototypes and First Articles

Request T1 or first-article samples to evaluate surface finish, button feel, and color accuracy. A strong partner will iterate quickly based on feedback.

Communication and Project Management

Because of time-zone differences, a responsive engineering team and English-speaking project manager are essential. Many leading Chinese manufacturers provide online project dashboards and weekly progress reports.

4. Cost, Lead Time, and Logistics of Calculator Molds

Mold Cost: Depending on complexity, calculator molds typically range from USD 5,000–15,000. A good manufacturer will amortize mold costs over large production runs to reduce per-unit pricing.

Production Cycle: From final design approval to mass production, expect 6–10 weeks.

Shipping: Air freight suits small, urgent orders, while sea freight is economical for large volumes. Your supplier should assist with customs documentation and tariff classification to avoid delays.

5. Case Snapshot: A Brand Promotion Success

Shenzhen-based China plastic injection molding manufacturer was contracted by an overseas stationery firm to deliver 20,000 custom calculators with logos for a back-to-school promotion. They managed to produce molds within four weeks, pilot run samples in week five, and begin full production from week seven. The calculators featured a dual-color logo received through pad printing and arrived in branded gift boxes in less than three months, well ahead of the start of the campaign.

6. Injection Molding Future Trends in Branded Electronics Manufacturing

Sustainability is becoming a key differentiator. Leading Chinese molders now offer bio-based or recycled plastics, enabling brands to market eco-friendly credentials. New processes like insert molding and two-shot molding offer possibilities for hybrid materials and blended-in-soft-touch grips, giving calculators the ability to cut through noise in markets.

7. Conclusion

From design to shop floor for a branded plastic electronic product such as a logoed calculator, it takes more than a creative design. It is a function of getting the right China plastic injection molding factory with knowledge of precision tooling, material science, and global quality standards.

Having the right supplier facilitates brands to comfortably turn bright ideas into durable, beautiful products that delight customers and support brand image.